The Restoration Story

The loco has been under the Trust's ownership since 2016 and this page provides a timeline for each year of restoration.

For a "taster" of the content, there follows a selection of the work undertaken

And a selection of images of the Rivetting project

The Lottery Heritage Funded project on Rivetting will provide a lasting legacy as there is still much to do on the loco in this area - the photo galleries in the main article illustrate the project from the start.

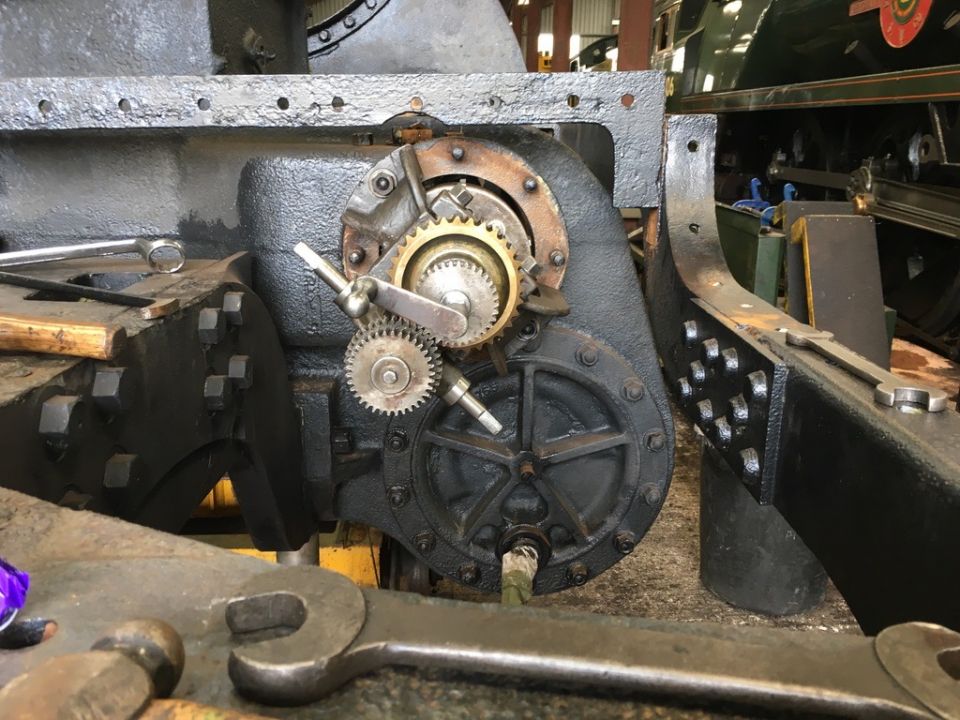

Other work underway is the refurbishment of the Reversing mechanism - this has been supported by grants from The Rowlands Trust and The Summerfield Charitable Trust. We would like to express our sincere thanks to them for their support

Most of our volunteer's efforts at the start of the year must necessarily be devoted to the winter maintenance tasks on working locomotives so there is a limit to what we are able to do. However, our contractors at Roach Engineering are progressing our new drag box. The photo shows it part machined - it is now finished and awaiting delivery to Toddington As you can see, its a big chunk of metal! It will be really good to get this in place on the loco.

As the year progressed, the new rear drag box replaced the old, badly corroded one. The picture below shows it temporarily fitted to get everything lined up - not as simple as it sounds as the years of service and the wait for restoration have caused varying amounts of corrosion to the frames but eventually we were happy with the fit and drilling of the new casting could commence.

The next photograph shows the first of the hot metal rivets in place.

To ensure there is no movement, the temprary bolts are removed only as each rivet is put in place. The bolts that are left can only be replaced by rivets when the side pieces of the rear assembly are put in place - but before this happens these pieces need to have some corrosion cut out and a snew section welded in - the photo below shows one with the old cut out and the new piece ready to go in - as can be seen it is a substantial section.

To fit in the new drag box, the "step supports" had to be removed to allow access - once removed these were seen to need some remedial work with badly corroded sections cut out and new platework welded in - this formed part of the training for our volunteers on an arc-welding course. We also decided that two of the steps themselves were beyond repair and one had been lost prior to our ownership so three new steps have been manufactured - again part of the training course.

Three trainees, under supervision can be seen fitting in a new section prior to welding.

As well as the rear drag box, the front one needs replacing - as it takes the whole weight of a train when running tender-first we can't take any risks with corrosion and the component was badly wasted. The front drag box comes as a "flat-pack" and has to be built up then drilled and riveted.

The picture above shows the bottom section ready for trial fitting - and below, the two sections temporarily bolted in place ready for the many holes to be drilled - both sides where it fits into the frsmes and the fron where the buffer beam will be fixed.

As with the rear, some of the supporting platework has some severe corrosion and we have cut ourt and replaced where necessary -below are two sections showing the wasted pieces

And below is the new section in place - we did find some "weathered" plate so it does match quitre well!

And below is the new section in place - we did find some "weathered" plate so it does match quitre well!

We have also made some more progress with the overall rivetting project - the new footplating we have made needs lots of holes drilled to match the existing fixing points. We have acquired a set of heavy duty, centre point punches - we choose the right size for the existing holes in the framework (and they are far from all the same size!), quick tap on the punch through the existing hole and mark the new platework then get to work with the mag drill. In the picture, the pilot holes have been drilled and Roger is about to start on the final size holes.

Now we have the funds (thanks to you, our supporters) for the new smoke box, we are getting quotes for the next stage - this will be the purchase of the door ring and the door itself. We have bought a new "curve mag drill" which will be invaluable in drilling the many holes both for the door end and for attachment to the boiler in due course.

In the machine shop at Toddington, our eccentric straps have been completed - a next stage is to have the eccentrics themselves machined. To progress this we have acquired a "dummy axle" that will be used to mount the eccentrics in the machine shop and get them true. Then will come the application of the bearing surface of white metal - to get ready for this stage we have sourced 50kg of (very expensive) ingots of the metal. Fortunately, the material machined off can be recycled.

The new rear eccentric straps matched with the existing parts - all the bolts that hold them together had to be made to match.

Metal restoration has played a large part in our work to date - hardly surprising considering the many years in the open since withdrawal in 1963!

The reverser frame is largely in good condition but wioth some localised corrosion where the damp coal dust accumulated under the cab floor - here it is when still attached to the rusting floor

The frame was removed and the rusted section cut out.

A new piece was ordered and then carefully cut to the exact size to match - we cut the corroded sections well back to get a really solid repair. The edges were then shaped to allow a good weld to made - here we are ready clamped up for the welder.

2021

New frame stretcher – ready for riveting in place.

Badly corroded steelwork.

New replacement pieces being fabricated.

The new pieces clamped in place – ready for welding then the whole section will be riveted in place – once this is secure, the old buffer beam can be removed and the new one riveted. Below the new section, the drag box can be seen – this will also be replaced as part of the riveting exercise.

Here can be seen some sections of new footplating - as the frames are not quite "square" anymore (due to years of wear and tear) some trimming is needed then drilling will be needed to match the rivet holes in the supporting frames - then we can rivet the platework into place.

We did find one of the arms that supports the outer frame in position had a major problem - Like many of these components, it had been repaired during its BR service days but not very well! The piece was removed - it had been welded on as well as riveted - and can be seen below with the detached end plate.

and below is the repaired section ready for re-riveting into place

Work has been undertaken on the horns in preparation for the horn grinding - here is Dave at work with the rotary wire brush and the finished surface

Pitting can be seen on the cleaned surface - the horn grinding will result in a perfectly flat section - measuments have shown that even when ground, we can have years of service from these components.

Work has also been underway on our axle boxes - these have all been thoroughly cleaned prior to refurbishment. Unfortunately, during the years in storage four of the axlebox underkeeps have been removed and most likley used on other locomotives - we have ordered four new castings which were delivered in the Autumn - these will then need some machining before being ready to fit. The wooden pattern for the castings are pictured - looks complicated but the foundry seem to understand whats was needed

!

The new castings went on display at the november Gala

The top covers of the axleboxes have badly corroded and require replacement - 8 new ones have been made (two pictured below). These now require drilling to match the individual boxes.

And from the machine shop - refurbished brake hangers

A batch of clack valves - one finished and lots of components for the rest - at the back of the photo csn be seen the brass bar that the valve parts were turned from

To allow restoration work on the timing mechanism of the loco, a number of the components must be removed (carefully!) before they're can be overhauled. One of the rocker arms has proved very stubborn and has resisted the efforts of copper hammers, oxy-acetelyne torchs and a hydraulic press - part of the problem being the difficulty in applying the ram of the press. To solve the issue, a former has been made to fit over a bracket on the frames - this will allow the full pressure from the hydraulic ram to be applied - hopefully it will now come apart. The specialy made former is pictured below

Here is the chairman, in very pensive mood, operating the hydraulic press during one the earlier attempts to free the part

The cab roof was taken to Tyseley to be rolled into shape - pictured on its return with the original framework angleiron.

Now fitted to the cab and the whole trial mounted into position

2020

The eccentric straps have progressed but there is still some way to go before these are completed

Axle boxes all cleaned ready for refurbishment

The accomodation bogies were assembled and painted - the wheels came as castings and needed machining for axles and greasing points

Help came from the Lottery Heritage Fund with a grant for additional small tools (to reduce sharing) and lots of PPE to ensure we could make progress as soon as some restrictions were lifted

This time its Tina in full protective equipment prior to using the angle grinder - these rivets will not give up without a real fight!

Work continued to remove the rear buffer beam and frame stretcher in preparation for new steelwork being riveted in place - here Andrew is drilling a pilot hole before using the mag drill (seen in position behind him) to remove the old rivets

The finished valve bore - this was liberally coated with petroleum jelly and wooden covers fitted to ensure no deterioration

The equipmemt itself is "heritage" having been rescued from a BR workshop

The valve chest boring was completed under the supervision of contractors from Tyseley Loco Works - Stuart can be seen setting up the equipment

Work on the wheelsets was completed at South Devon Engineering - here the old tyres are being removed prior to fitting the new ones:

Painting next - the sets received 2 coats of anti-corrosive primer, 3 coats undercoat, 3 coats black gloss - and the machined parts were liberally coated in waxoyl and denso tape to ensure no rusting before we are ready to rewheel

The wheelsets arrive back at Toddington from South Devon

The wheelsets arrive back at Toddington from South Devon

Old Tyres off – the gas burners are being positioned around the old tyre. When the heat has been applied for a while a quick tap with a sledgehammer and the old metal falls off.

New Tyres on – the process is reversed to fit the new one – the tyre is heated and then the wheel centre dropped in – cooling and contraction makes a snug fit then a retaining system (the Gibson Ring) is fitted to make completely secure.

Extract from the South Devon Engineering Facebook page goes with the image above.

Heritage railway engineers at the South Devon Railway (SDR) know only too well that fitting new tyres to a steam locomotive is a lengthy and complex process, and it’s certainly nothing like the average tyre change at a garage!

Unlike your standard car tyre, these four to six feet diameter wheels take virtually a full day to fit each one and require the use of some heavy-duty, traditional engineering machinery. The SDR can also fit even bigger wheels well over six feet in diameter as well, and smaller ones too. Most steam locomotive have at least four large driving wheels, and often six, but sometimes eight, plus two or four wheels on ‘pony trucks’ at the front or back!

The tyres are made from top-quality steel sourced from South Africa, which means it can take six to nine months to get the different sizes ordered and shipped to the UK.

In the attached pictures, the re-tyring process is shown whereby the engineers place the now machined steel tyre inside a gas-powered hearth. This heats up the metal tyre ring until it’s ‘cooked’ sufficiently so that it expands enough to then drop the wheel centre into the middle of the tyre very carefully.

The steel tyre then cools, causing it to shrink to fit the wheel centre and it is then secured by either using rivets; ‘double nip’ or Gibson ring methods later.

2019

2018

2017

Pair of expansion links acquired – nearly new and surplus to another owning group’s requirements – half the price of new.

Non-destructive testing of the boiler undertaken - to establish detailed restoration requirements and where platework needs to be replaced. We are already aware that the lower firebox outer steel platework, some doorplate and throatplate will have to be replaced but no further unwelcome news.

2016

The Restoration Story begins, but to start you have to take everything apart!

Smoke box removed – badly corroded and not re-usable, but the chimney was salvaged.